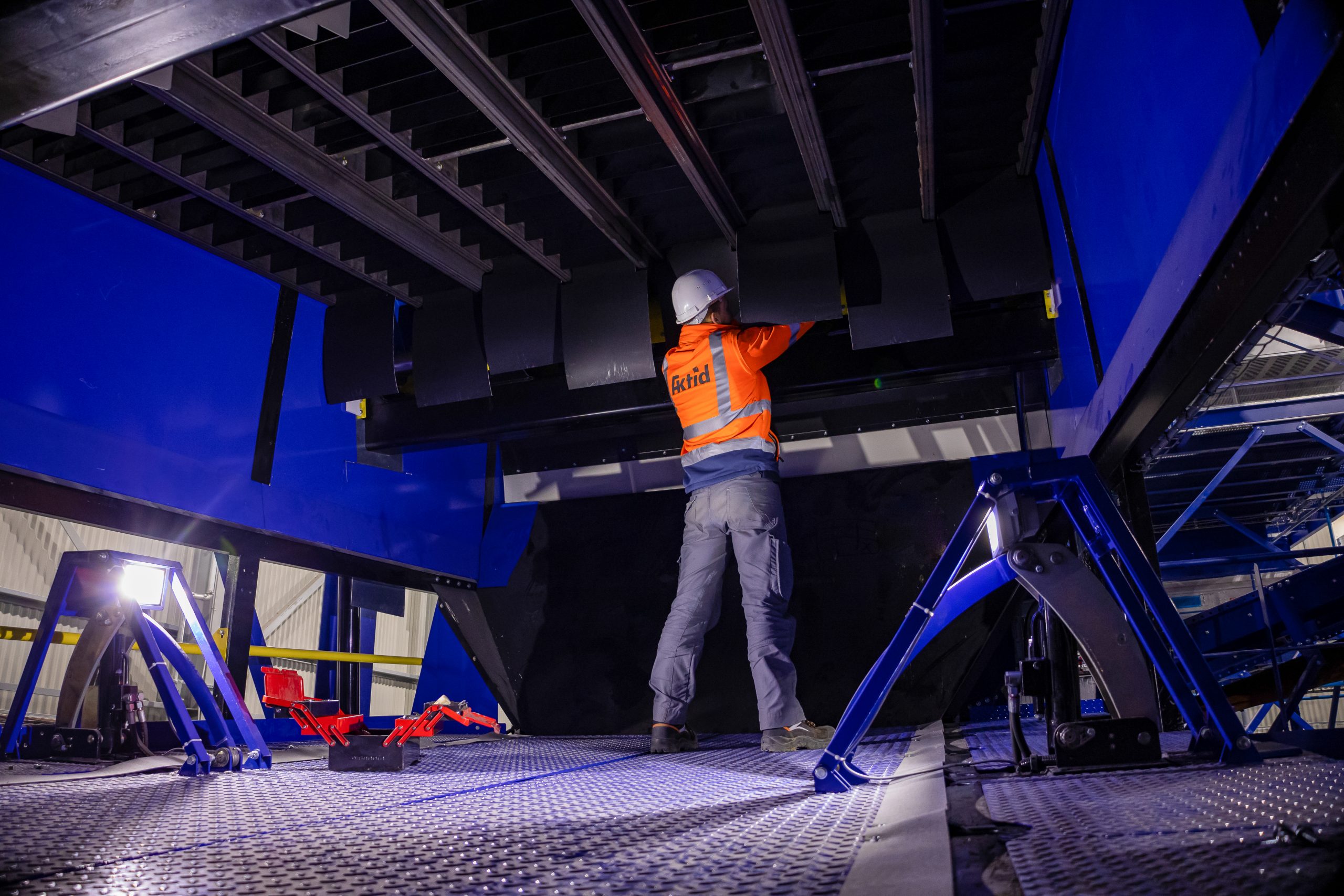

AKTID,

CREATING

TOMORROW’S WASTE-SORTING CENTRES

Aktid is a French company that designs and builds turnkey waste sorting and processing facilities for all types of solid waste, including household waste, industrial waste, construction waste and plastics recycling.

We are also experts in building units to produce solid recovered fuel.

We develop new processing lines, from the simplest to the most complex, and optimis existing sorting units. Our solutions are designed for not only independent operators but also large groups and local authorities.

Today, with around 150 facilities built since 1995, Aktid has become the French standard-setter for sorting centres.

Stay In Touch